Topics covered in this article include:

- Introduction

- Measurement Summary

- Instructions

- Available Tests

- Image Acquisition Suggestions

- Detailed Discussion of Measurements

Introduction

The water bath phantom is used to test uniformity and HU scaling.

Measurement Summary

The analysis provides the following results:

- Vertical profile and the corresponding fitted curve

The measurements are completely automated, requiring the user only to drag and drop the image set into the web-based software interface. A detailed report is created.

Instructions

The test requires one or more DICOM images. If you have added the appropriate tests to your template, you will be able to select the test from the Type drop-down, as shown below. There are limited options for encoding the analysis into the filename, but this is not the the suggested method.

Alternatively, limited capabilities to manually identify planar images using DICOM tag values have been added to the image processing system. For the Waterbath analysis, add CTP777 (case insensitive) to The PatientID, StudyID, or SeriesDescription DICOM tag. For more details see Manual Identification of RT Planar Images and Individual Catphan Slices through DICOM tags.

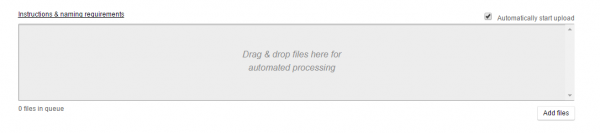

When imaging QA tests are added to templates an upload control will appear in the scheduled QA's data entry screen allowing the user to upload images for automated analysis.

To add files to the upload queue simply drag them from a Windows Explorer folder to the drag and drop folder and release them. Alternatively, by clicking on the Add Files button to the lower right of the control a windows file selection dialog will open and files can be selected for upload. Under either method, multiple files may be selected for upload at once.

If the automatically upload checkbox is checked (the default) then file uploading will start immediately as files are added.

If the automatically upload button is turned to off the file upload process must be started manually clicking the Start upload button on the lower right of the control. To clear the upload queue click the Clear button.

Once file series have been uploaded they will be displayed below the upload control. To remove a series from the queue click the Cancel button beside the series. To start processing click the Start Processing button. A description for the image series can be added at this point. Click the Edit button next to the series. Type a description for the series into the text box that appears below Description and either click Save or press the enter key. The description can also be edited after the images have been processed. Descriptions will appear in the report with the analysis of the series.

While files are being processed users may perform other tasks such as data entry.

Available Tests

The following tables show the tests to select in the template builder corresponding to the supported analyses.

| Analysis | Template Section | Subsection |

|---|---|---|

Waterbath Analysis |

CT Waterbath Phantom |

|

Image Acquisition Suggestions

| Parameter | Value | Notes |

|---|---|---|

| Scan Protocol | Regulatory or vendor recommendation may be available. | |

| Phantom diameter and shape | 20cm head / 30cm or more for body | The CT number vary considerably depending on phantom size and shape (eg, round or oval). Various annuli are available. |

| Scanning FOV | 300>FOV>200mm | Note whether you intend to use a head or body protocol. The calibration (beam hardening, etc) may be different. The scan FOV must include the uniformity module. |

| Reconstructed FOV | 210>FOV>200mm | Should match the phantom diameter. If body annuli are used, the scanned FOV and reconstructed FOV must be large enough to include the uniformity module. |

| mAs | Chose the current and scan time of interest | Rings and bands and other nonuniformities may not be seen with high noise - low dose scans, but will possibly be seen with higher dose and lower noise. |

| kVp | Select the kVp of interest | The calibration of the system needs to be matched to the kVp used. |

| Reconstruction kernel | Select the kernel of interest | Noting if this is in head or body mode for certain scanners and reflect the scan protocol of interest. |

| Scanning mode | Sequential or spiral | Spiral may be used, but making sure there is enough water or uniform material so that the slice of interest in spiral scanning has the same material above and below the slice of interest. Sequential centered slices will minimize this risk. |

Detailed Discussion of Measurements

The precision of a CT system is evaluated by the measurement of the mean value and the corresponding standard deviations in CT numbers within a region of interest (ROI). These measurements are taken from different locations within the scan field.

The algorithm provides vertical and horizontal line profiles across the uniformity module. The points on the plot are an average over 5 columns of pixels. The plot is then smoothed further to reduce noise before the fitted curve is completed. To calculate the uniformity index for the horizontal and vertical profiles, the maximum and minimum y-axis CT values (HU) from the fitted curve are entered into the following equation: 1 - (CTmax-CTmin) / (CTmax+CTmin)

The closer a value is to "1", the more uniform the image.

The phenomenon of “cupping” or “capping” of the CT number may indicate the need for calibration.

In the graph below, the upper limit is determined by adding 40 HU to the Mean CT number of the Center ROI. The lower limit is determined by subtracting 40 HU from the Mean CT number of the Center ROI.

Vertical Profile and Corresponding Fitted Curve

The profile plotted below is a line profile from a vertical line across the uniformity module. The points on the plot are an average over 5 columns of pixels. The plot is then smoothed further to reduce noise before the fitted curve is completed.

Horizontal Profile and Corresponding Fitted Curve

The profile plotted below is a line profile from a horizontal line across the uniformity module. The points on the plot are an average over 5 rows of pixels. The plot is then smoothed further to reduce noise before the fitted curve is completed.

Uniformity Index (Vertical/Horizontal)

To calculate the uniformity index for the horizontal and vertical profiles, the maximum and minimum y-axis CT values (HU) from the fitted curve are entered into the following equation: 1 - (CTmax-CTmin) / (CTmax+CTmin)

The closer a value is to "1", the more uniform the image.

Mean CT Value - Center Region

The mean CT number value in the center region of interest (ROI) is used as a reference for other uniformity calculations and can be viewed in the "Noise and Mean Values Plot".

Noise and Mean Values Plot

In this plot, the mean CT number (HU value) for each region of interest (ROI) is displayed as the blue column. The noise, displayed as the red column, is the standard deviation of HU values within each ROI. The upper and lower limits, indicated by the green horizontal lines, are +/- 4HU from the mean HU value of the center ROI as required by the IEC standards.

Absolute Difference from Center in Regions of Interest

The absolute difference in mean CT number from the center ROI is calculated for each ROI.

Noise

Noise is calculated as the standard deviation of CT numbers from a center ROI that encompasses 40% of the uniformity module.

Below is an example of the report generated: